UNEC Journal of Engineering and Applied Sciences Volume 4, No 2, pages 37-46 (2024) Cite this article, 1532 https://doi.org/10.61640/ujeas.2024.1204

The optical bandgap is a vital characteristic of semiconductor materials [1]. Something else, the zone is called “indirect” transmission capacity [2].

To degree the optical properties of semiconductors, a UV spectrometer is utilized, which comprises of a light source of the desired ghostly run and a gadget for measuring the transmittance of KBr unmistakable and IR spectra, with a monochromator.

Specular reflection is coordinate radiation from the surface of the film, comparing to Snellius law of reflection. Diffuse reflection (DR) is the wavelength-dependent retention of radiation occurrence and scattered on a film and inside a fabric. A few of this radiation in the long run clears out the bulk test in all bearings. Measuring diffuse reflectance employing a UV spectrophotometer could be a standard method for deciding the optical properties of lean movies [3-10].

In specific, Eg is an imperative property of semiconductor nanofilms that decides their appropriateness in optoelectronic applications. In DR spectroscopy, there are numerous strategies for getting lean movies [11-17].

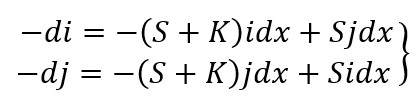

The thought of utilizing DR spectra gotten from semiconductor nanostructures to calculate the band hole was to begin with proposed by the Kubelka-Munk hypothesis [12]. The hypothesis at first portrays the development of light inside a light diffusing design and is based on two differential conditions:

(1)

(1)

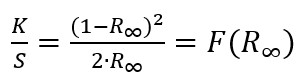

The Kubelka-Munk hypothesis is substantial for molecule sizes comparable to or littler than the wavelength of occurrence light, and DR does not take under consideration the auxiliary commitments of reflection, refraction and diffraction. In case the thickness of the sample is inside worthy limits, it'll not influence the reflection. Therefore, the Kubelka-Munk equation can be written for any wavelength:

(2)

(2)

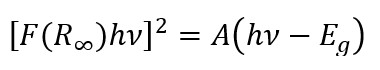

If the incident radiation is perfectly scattered, the absorption coefficient K is 2α. In this case, assuming that the scattering coefficient S is constant with respect to the wavelength, the Kubelka-Munk function is proportional to the absorption coefficient α, and applying equation (2), we obtain the following relation [18- 20]:

(3)

(3)

In this work, the band gap (Eg) of chromium silicide films was determined based on the Tauc relation given in equation (3). For a direct gap semiconductor material, the Tauc relation is given by:

(4)

(4)

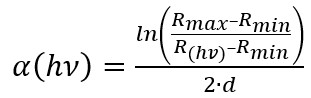

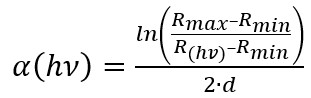

Where α is the linear absorption coefficient, ν is the frequency of light, A is the proportionality constant. n is an indicator that determines the type of interband transitions, n is taken equal to 1/2 for materials with a direct bandgap (1/2; 3/2; 5/2; 2 and 3 for direct and indirect allowed and forbidden transitions, respectively). The spectral dependences of the absorption coefficient α(hv) were calculated using the following analytical equations using the formulas [21- 25]:

(5)

(5)

Experimental samples of chromium silicide were obtained by the ion-plasma method using an improved EPOS-PVD-DESK-PRO magnetron sputtering installation [26-27], the diagram of which is shown in figure 1.

Before applying the film, the surface of the silicon wafers was subjected to a two-stage treatment: primary cleaning with 30% diluted hydrofluoric acid, then the surface was subjected to secondary cleaning with a high-energy Ar+ ion-plasma flow inside the magnetron chamber. Thin films of CrSi2/Si(111) were formed on polished substrates heated to 480 K using a special heater in a vacuum of 1.2·10-4 mbar by the solid-phase ion-plasma method. During the experiment, the substrates were mounted on a rotating carousel holder at a distance of 150 mm from the surface of the magnetron target. The magnetron power supply current is 716 mA, power 263 W, voltage 320 V. Thin films of CrSi2 are formed from a CrSi2 target with a purity of 99.5% by the solid-phase ion-plasma method (figure 2a). Elemental analysis of the CrSi2 target was performed using energy dispersive spectroscopy (figure 2b).

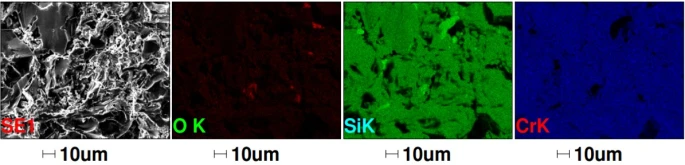

Figures 3, 4 show 3D and 2D SEM images of chromium disilicide nanofilm grown by magnetron sputtering, respectively. The thickness of the resulting CrSi2 film is 62.0 nm. A thin surface layer is evenly distributed over the surface. The elemental composition of the films was studied using energy-dispersive X-ray spectroscopy (EDX). In figure 5 shows an SEM image of the surface of the CrSi2 film. The studies were carried out using a Quanta 200 scanning electron microscope. Table 1 shows the percentage of elements in the CrSi2 film.

According to the results of measurements using energy dispersive X-ray spectroscopy (EDX), the elemental composition of the films is as follows: Si - 33.6%, Cr - 62.32% and a very small amount of O - 4.08%. As can be seen from the information displayed, the test contains the foremost chromium and silicon by mass and nuclear rate and exceptionally small oxygen. The table appears that oxygen is display within the littlest amount. The arrangement of CrSi2 lean movies on the silicon surface can be clarified based on the stoichiometry comes about.

To study the distribution of elements, the film surface was examined at an angle of 48 degrees. To study the internal structure of the sample, a cross section of the CrSi2/Si boundary was taken.

figure6

Figure 6. Image elemental composition map:

a) Depth profile of a CrSi2 film b) image of the low amount of oxygen in the sample c) image of the presence of Si in the film d) depth profile of Cr in a thin film

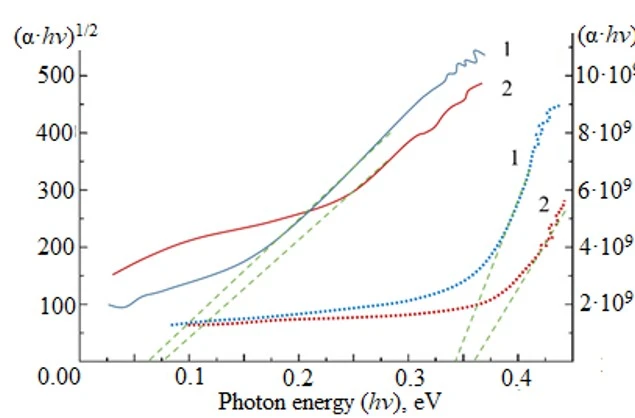

Constrained by data around the vitality structure and the nature of interband moves within the CrSi2 film, equation (4) was gotten by approximating the retention information gotten utilizing the Kumar and Kubelka-Munk models, accepting the parameter n to be a variable esteem. The best fit (correlation coefficient was 0.986) was achieved with n values of 2 and 0.5 for CrSi2. Figure 7 shows the spectral dependences of absorption in the coordinates of optical transitions based on the Kubelka-Munk and Kumar approach, calculated using formulas (2) and (4). Based on these dependencies, the values of the band gap (optical band gap) were obtained. Approximation of the linear range of the spectral dependence by a straight line up to the intersection with the x-axis gives values of 1.1512 eV and 0.3543 eV for Si(111) and CrSi2/Si(111) thin films, respectively.

The reason of this work is to think about the morphology, basic composition and optical and electronic characteristics lean movies of CrSi2 gotten by the solid-phase ion-plasma strategy (figure 8).

To degree the band hole of lean chromium disilicide movies gotten by the solid-phase ion-plasma strategy utilizing IR retention and UV spectroscopy, the dependences of the UV retention coefficient and refractive records of the movies on the vitality of occurrence photons were measured (figure 9).

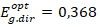

The optical electronic band gaps of amorphous and polycrystalline CrSi2 thin films were determined by measuring the IR reflectance and transmittance of 62 nm thick CrSi2 deposited on an Egopt silicon substrate. The direct and indirect optical band gap values were determined using Tauc plots, figure 10. A sharp increase in photon energy above 0.063 and 0.34 eV can be observed for amorphous and nanostructured CrSi2 thin films, respectively, which confirms the semiconductor properties of polycrystalline CrSi2 films. Tauc plots show that CrSi2 thin films have an indirect band gap (energy of indirect allowed optical transitions):  eV and

eV and  eV, respectively, and direct band gap (energy of direct allowed optical transitions)

eV, respectively, and direct band gap (energy of direct allowed optical transitions)  eV and

eV and  eV. The instability was assessed based on a straight relapse fit to the chosen information extend. Hence, lean movies of shapeless CrSi2 are narrow-gap semiconductors, which clarifies the moo electrical resistance and semimetal-like behavior. With fractional crystallization, an increment within the band hole can be observed, although its esteem isn't rise to to that of single-crystal CrSi2 (0.35 eV). The coming about electronic structure is reliable with an increase in electrical resistance and a diminish within the measured carrier concentration, which can be clarified by a diminish within the level of abandons and nanostructuring amid tempering. Such changes within the electronic structure of CrSi2 lean movies due to crystallization are steady with other optical transmittance estimations [28-30].

eV. The instability was assessed based on a straight relapse fit to the chosen information extend. Hence, lean movies of shapeless CrSi2 are narrow-gap semiconductors, which clarifies the moo electrical resistance and semimetal-like behavior. With fractional crystallization, an increment within the band hole can be observed, although its esteem isn't rise to to that of single-crystal CrSi2 (0.35 eV). The coming about electronic structure is reliable with an increase in electrical resistance and a diminish within the measured carrier concentration, which can be clarified by a diminish within the level of abandons and nanostructuring amid tempering. Such changes within the electronic structure of CrSi2 lean movies due to crystallization are steady with other optical transmittance estimations [28-30].

figure10

Figure 10. Tauc diagrams for indirect and direct band gaps of amorphous (sputtered) and nanostructured (annealed) CrSi2 thin films.

1 –– Amorphous film, 2 –– Nanostructured film. The green dotted lines show the linear fit to the Tauc plot

The hv esteem compares to the width of the tails of localized states close the band edge and is gotten from the variety plot close the band hole EU. Due to the diminish within the imperfection level ln(α), a sharp diminish in nano crystallization is watched with EU values of 0.163 eV and 0.346 eV for the sputtered and strengthened movies, separately. In this way, the band tails are nearly indistinguishable to the EU band crevice values and can clarify the quasi-metallic behavior of undefined lean movies.

The gotten values of the vitality crevice and phonon vitality for lean movies of Si(111) and CrSi2/Si(111) are summarized in table 2.

The results of spectroscopic studies illustrating the absorption spectra for Si(111) and Si(111) with a CrSi2 film 62 nm thick are presented in Figure 11. It can be seen that in the case of pure silicon hv ≈ 0.22 ÷ 0.93 eV, the transmission coefficient T ≈ 0.84, and the reflection coefficient R ~ 0.2. In the case of the CrSi2/Si(111) film in the range hv ≈ 0.23 eV, T ≈ 0.64 and R ≈ 0.32. In the second part of the I(hv) dependence, I drops sharply to zero. From the edge of the absorption spectrum, by extrapolating part of the curve onto the hv axis, the approximate value of the band gap is determined. It can be seen that Eg ~ 1.14 eV for Si(111) and Eg ~ 0.34 eV for CrSi2 at room temperature.

In this work, thin films of CrSi2 with a purity of 99.5% are formed from a CrSi2 target by a solid-phase ion-plasma method. The morphology and elemental composition of the thin films were analyzed by scanning electron microscopy using energy dispersive X-ray spectroscopy. Band gap widths of amorphous and polycrystalline CrSi2 thin films were measured using different methods. A comparative analysis was conducted. The optical absorption spectra of the films were studied and as a result approximate band gap values of Eg ~ 1.14 eV for Si(111) and Eg ~ 0.34 eV for CrSi2 were determined at room temperature.

We believe that this research will serve to strengthen scientific research on determining the bandgap of silicide thin films.

1 M.T. Normuradov, I.R. Bekpulatov, G.T. Imanova, B.D. Igamov, Advanced Physical Research 4(3) (2022) 142.

2 I.R. Bekpulatov, G.T. Imanova, T.S. Kamilov, B.D. Igamov, I.K. Turapov, International Journal of Modern Physics B 37(17) (2023) 22350164. https://doi.org/10.1142/S0217979223501643

3 L.N. Agayeva, N.A. Akhmedov, G.T. Imanova, Materials Research Innovations 28(7) (2024) 550. https://doi.org/10.1080/14328917.2024.2342013

4 J. Georgin, D.S.P. Franco, C.G. Ramos, H.N. Tran, A. Benettayeb, G. Imanova, I. Ali, Journal of Molecular Liquids 402 (2024) 124786. https://doi.org/10.1016/j.molliq.2024.124786

5 I. Ali, G. Imanova, T. Agayev, A. Aliyev, T.A. Kurniawan, M.A. Habila, Radiation Physics and Chemistry 223 (2024) 111902. https://doi.org/10.1016/j.radphyschem.2024.111902

6 I. Ali, T. Kon’kova, E. Liberman, A. Gaydukova, T.A. Kurniawan, S.A. Aldossari, G. Imanova, X.Y. Mbianda, Inorganic Chemistry Communications 167 (2024) 112747. https://doi.org/10.1016/j.inoche.2024.112747

7 I. Ali, G. Imanova, T. Agayev, A. Aliyev, T.A. Kurniawan, M.A. Habila, Radiation Physics and Chemistry 224 (2024) 112002. https://doi.org/10.1016/j.radphyschem.2024.112002

8 M. Xiang, N. Wang, L. Sun, L. He, L. Zhong, G. Imanova, S. Komarneni, W. Hu, Separation and Purification Technology 354(1) (2025) 128667. https://doi.org/10.1016/j.seppur.2024.128667

9 L. Zhu, S. Zhou, H. Cheng, J. Ma, G. Imanova, S. Komarneni, Journal of Environmental Chemical Engineering 12(5) (2024) 113591. https://doi.org/10.1016/j.jece.2024.113591

10 I. Ali, H. Mahmudov, G. Imanova, T.A. Kurniawan, M.A. Habila, Materials Research Innovations 28(4) (2024) 1. https://doi.org/10.1080/14328917.2024.2382393

11 G. Imanova, Modern Physics Letters B 38(22) (2024) 2450206. https://doi.org/10.1142/S0217984924502063

12 G.T. Imanova, T.N. Agayev, S.H. Jabarov, Modern Physics Letters B 35(02) (2021) 2150050. https://doi.org/10.1142/S0217984921500500

13 B.E. Umirzakov, G.T. Imanova, I.R. Bekpulatov, and I.Kh. Turapov, Modern Physics Letters B 37(24) (2023) 2350078. https://doi.org/10.1142/S0217984923500781

14 B.D. Igamov, G.T. Imanova, A.I. Kamardin, I.R. Bekpulatov, Integrated Ferroelectrics 240(1) (2024) 53. https://doi.org/10.1080/10584587.2023.2296317

15 A.E. Shumskaya, S.N. Lemesonok, O.A. Alisienok, V.E. Kovalev, S.I.Korzan, E.A. Kulesh, G.T. Imanova & S.H. Jabarov, Materials Research Innovations 28(5) (2024) 379. https://doi.org/10.1080/14328917.2024.2366728

16 F.К. Khallokov, G.T. Imanova, S.Kh. Umarov, M.Yu. Tashmetov, N.Z. Gasanov,Z.U. Esanov, I.R. Bekpulatov, Materials Research Innovations (2024) 1. https://doi.org/10.1080/14328917.2024.2363583

17 S.H. Jabarov, A.K. Nabiyeva, E.M. Huseynov, Journal Porous Materials 31 (2024) 1811 https://doi.org/10.1007/s10934-024-01632-6

18 B.E. Umirzakov, Zh.M. Jumayev, I.R. Bekpulatov, I.Kh. Turapov, G.T. Imanova & N.P. Farmonov, Materials Research Innovations 28(3) (2024) 1. https://doi.org/10.1080/14328917.2024.235082

19 M.N. Mirzayev, G.T. Imanova, D. Neov, M. Rasoul, I.R. Bekpulatov, F.K. Khallokov, E.P. Popov, K. Hasanov, S. Isayeva, B. Mauyey, D.M. Mirzayeva, F. Tatardar, M. Dinu, G. Kaminski, A. Vladescu, Journal of Porous Materials 31 (2024) 1531. https://doi.org/10.1007/s10934-024-01627-3

20 I.R. Bekpulatov, G.T. Imanova, B.E. Umirzakov, K.T. Dovranov, V.V. Loboda, S.H. Jabarov, I.X. Turapov, N.E. Norbutaev, Materials Research Innovations 28(4) (2024) 221. https://doi.org/10.1080/14328917.2024.2339001

21 G. Imanova, S. Jabarov, T. Agayev, Journal Porous Materials 31 (2024) 1135. https://doi.org/10.1007/s10934-024-01591-y

22 G.T. Imanova, Advanced Physical Research 2(2) (2020) 94.

23 B.E. Umirzakov, I.R. Bekpulatov, G.T. Imanova, I.Kh. Turapov, J.M. Jumaev, Eurasian Journal of Physics and Functional Materials 7(4) (2023) 249. https://doi.org/10.32523/ejpfm.2023070405

24 B.D. Igamova, G.T. Imanova, A.I. Kamardin and I.R. Bekpulatov, Integrated ferroelectrics 240(1) (2024) 53. https://doi.org/10.1080/10584587.2023.2296317

25 F.К. Khallokov, G.T. Imanova, S.Kh. Umarov, M.Yu. Tashmetov, N.Z. Gasanov, Z.U. Esanov, I.R. Bekpulatov, Materials Research Innovations (2024) 1. https://doi.org/10.1080/14328917.2024.2363583

26 B.D. Igamov, I.R. Bekpulatov, G.T. Imanova, A.I. Kamardin, D.A. Normurodov, Physics and chemistry of solid state 25(2) (2024) 421. https://doi.org/10.15330/pcss.25.2.

27 M. Оydinоv, B. Igаmоv, I. Bekpulаtоv, E. Аbdurаhmоnоv, G. Imanova, Chemical Bulletin of Kazakh National University 111(1-2) (2024) 28. https://doi.org/https://doi.org/10.15328/cb1371

28 I.R. Bekpulatov, G.T. Imanova, S.H. Jabarov, B.E. Umirzakov, K.T. Dovranov, V.V. Loboda, I.X. Turapov, N.E. Norbutaev, M.I. Sayyed, D.I. Tishkevich and A.V. Trukhanov, Journal of Materials Science: Materials in Electronics 35 (2024). https://doi.org/10.1007/s10854-024-13163-6

29 Z.A. Isakhanov, B.E. Umirzakov, G.T. Imanova, Optical Materials: X 24 (2024) 100354. https://doi.org/10.1016/j.omx.2024.100354

30 B.D. Igamov, G.T. Imanova, V.V. Loboda, V.V. Zhurikhina, I.R. Bekpulatov, A.I. Kamardin, Optical Materials: X 24 (2024) 100353. https://doi.org/10.1016/j.omx.2024.100353

K.T. Dovranov, G.T. Imanova, V.V. Loboda, M.T. Normuradov, I.R. Bekpulatov, Formation of CrSi2 film and measurement of optical band gap energy, diphenylcarbazide, and cetyltrimethylammonium bromide, UNEC J. Eng. Appl. Sci. 4(2) (2024) 37-46 https://doi.org/10.61640/ujeas.2024.1204

Anyone you share the following link with will be able to read this content:

This article is licensed under the Creative Commons Attribution ( CC BY 4.0 ) License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

M.T. Normuradov, I.R. Bekpulatov, G.T. Imanova, B.D. Igamov, Advanced Physical Research 4(3) (2022) 142.

I.R. Bekpulatov, G.T. Imanova, T.S. Kamilov, B.D. Igamov, I.K. Turapov, International Journal of Modern Physics B 37(17) (2023) 22350164. https://doi.org/10.1142/S0217979223501643

L.N. Agayeva, N.A. Akhmedov, G.T. Imanova, Materials Research Innovations 28(7) (2024) 550. https://doi.org/10.1080/14328917.2024.2342013

J. Georgin, D.S.P. Franco, C.G. Ramos, H.N. Tran, A. Benettayeb, G. Imanova, I. Ali, Journal of Molecular Liquids 402 (2024) 124786. https://doi.org/10.1016/j.molliq.2024.124786

I. Ali, G. Imanova, T. Agayev, A. Aliyev, T.A. Kurniawan, M.A. Habila, Radiation Physics and Chemistry 223 (2024) 111902. https://doi.org/10.1016/j.radphyschem.2024.111902

I. Ali, T. Kon’kova, E. Liberman, A. Gaydukova, T.A. Kurniawan, S.A. Aldossari, G. Imanova, X.Y. Mbianda, Inorganic Chemistry Communications 167 (2024) 112747. https://doi.org/10.1016/j.inoche.2024.112747

I. Ali, G. Imanova, T. Agayev, A. Aliyev, T.A. Kurniawan, M.A. Habila, Radiation Physics and Chemistry 224 (2024) 112002. https://doi.org/10.1016/j.radphyschem.2024.112002

M. Xiang, N. Wang, L. Sun, L. He, L. Zhong, G. Imanova, S. Komarneni, W. Hu, Separation and Purification Technology 354(1) (2025) 128667. https://doi.org/10.1016/j.seppur.2024.128667

L. Zhu, S. Zhou, H. Cheng, J. Ma, G. Imanova, S. Komarneni, Journal of Environmental Chemical Engineering 12(5) (2024) 113591. https://doi.org/10.1016/j.jece.2024.113591

I. Ali, H. Mahmudov, G. Imanova, T.A. Kurniawan, M.A. Habila, Materials Research Innovations 28(4) (2024) 1. https://doi.org/10.1080/14328917.2024.2382393

G. Imanova, Modern Physics Letters B 38(22) (2024) 2450206. https://doi.org/10.1142/S0217984924502063

G.T. Imanova, T.N. Agayev, S.H. Jabarov, Modern Physics Letters B 35(02) (2021) 2150050. https://doi.org/10.1142/S0217984921500500

B.E. Umirzakov, G.T. Imanova, I.R. Bekpulatov, and I.Kh. Turapov, Modern Physics Letters B 37(24) (2023) 2350078. https://doi.org/10.1142/S0217984923500781

B.D. Igamov, G.T. Imanova, A.I. Kamardin, I.R. Bekpulatov, Integrated Ferroelectrics 240(1) (2024) 53. https://doi.org/10.1080/10584587.2023.2296317

A.E. Shumskaya, S.N. Lemesonok, O.A. Alisienok, V.E. Kovalev, S.I.Korzan, E.A. Kulesh, G.T. Imanova & S.H. Jabarov, Materials Research Innovations 28(5) (2024) 379. https://doi.org/10.1080/14328917.2024.2366728

F.К. Khallokov, G.T. Imanova, S.Kh. Umarov, M.Yu. Tashmetov, N.Z. Gasanov,Z.U. Esanov, I.R. Bekpulatov, Materials Research Innovations (2024) 1. https://doi.org/10.1080/14328917.2024.2363583

S.H. Jabarov, A.K. Nabiyeva, E.M. Huseynov, Journal Porous Materials 31 (2024) 1811 https://doi.org/10.1007/s10934-024-01632-6

B.E. Umirzakov, Zh.M. Jumayev, I.R. Bekpulatov, I.Kh. Turapov, G.T. Imanova & N.P. Farmonov, Materials Research Innovations 28(3) (2024) 1. https://doi.org/10.1080/14328917.2024.235082

M.N. Mirzayev, G.T. Imanova, D. Neov, M. Rasoul, I.R. Bekpulatov, F.K. Khallokov, E.P. Popov, K. Hasanov, S. Isayeva, B. Mauyey, D.M. Mirzayeva, F. Tatardar, M. Dinu, G. Kaminski, A. Vladescu, Journal of Porous Materials 31 (2024) 1531. https://doi.org/10.1007/s10934-024-01627-3

I.R. Bekpulatov, G.T. Imanova, B.E. Umirzakov, K.T. Dovranov, V.V. Loboda, S.H. Jabarov, I.X. Turapov, N.E. Norbutaev, Materials Research Innovations 28(4) (2024) 221. https://doi.org/10.1080/14328917.2024.2339001

G. Imanova, S. Jabarov, T. Agayev, Journal Porous Materials 31 (2024) 1135. https://doi.org/10.1007/s10934-024-01591-y

G.T. Imanova, Advanced Physical Research 2(2) (2020) 94.

B.E. Umirzakov, I.R. Bekpulatov, G.T. Imanova, I.Kh. Turapov, J.M. Jumaev, Eurasian Journal of Physics and Functional Materials 7(4) (2023) 249. https://doi.org/10.32523/ejpfm.2023070405

B.D. Igamova, G.T. Imanova, A.I. Kamardin and I.R. Bekpulatov, Integrated ferroelectrics 240(1) (2024) 53. https://doi.org/10.1080/10584587.2023.2296317

F.К. Khallokov, G.T. Imanova, S.Kh. Umarov, M.Yu. Tashmetov, N.Z. Gasanov, Z.U. Esanov, I.R. Bekpulatov, Materials Research Innovations (2024) 1. https://doi.org/10.1080/14328917.2024.2363583

B.D. Igamov, I.R. Bekpulatov, G.T. Imanova, A.I. Kamardin, D.A. Normurodov, Physics and chemistry of solid state 25(2) (2024) 421. https://doi.org/10.15330/pcss.25.2.

M. Оydinоv, B. Igаmоv, I. Bekpulаtоv, E. Аbdurаhmоnоv, G. Imanova, Chemical Bulletin of Kazakh National University 111(1-2) (2024) 28. https://doi.org/https://doi.org/10.15328/cb1371

I.R. Bekpulatov, G.T. Imanova, S.H. Jabarov, B.E. Umirzakov, K.T. Dovranov, V.V. Loboda, I.X. Turapov, N.E. Norbutaev, M.I. Sayyed, D.I. Tishkevich and A.V. Trukhanov, Journal of Materials Science: Materials in Electronics 35 (2024). https://doi.org/10.1007/s10854-024-13163-6

Z.A. Isakhanov, B.E. Umirzakov, G.T. Imanova, Optical Materials: X 24 (2024) 100354. https://doi.org/10.1016/j.omx.2024.100354

B.D. Igamov, G.T. Imanova, V.V. Loboda, V.V. Zhurikhina, I.R. Bekpulatov, A.I. Kamardin, Optical Materials: X 24 (2024) 100353. https://doi.org/10.1016/j.omx.2024.100353