UNEC Journal of Engineering and Applied Sciences Volume 3, No 1, pages 21-27 (2023) Cite this article, 3243 https://doi.org/10.61640/ujeas.2023.0504

In the energy system thermal power plants using fossil fuel dominate. Currently, the thermal energetics creation of energy blocks operating with higher than critical (P0 = 24 MPa, t0 = 560 0C), super critical (P0 = 31-32 MPa, t0 = 560-600 0C), ultra-supercritical (P0 = 37-38 MPa, t0 = 700 0C) parameters of water is one of the urgent issues. One of the main ways to increase the efficiency of a thermal power plant is to increase the initial parameters of steam. In this case, the turbine power increases, the efficiency coefficient increases, the efficiency of the station increases in a whole. Calculations show that if we compare the thermal efficiency of a 300 MW unit operating at higher than critical parameters, as well as a unit operating at the same capacity with a super critical parameter, 7% on specific fuel consumptionis saved [1]. The 300 MW unit burns 70 tons of natural fuel per hour. If this unit works with super critical parameters, then one block saves 4.9 tons of fuel per hour. If we take into account that the station has at least 3-4 units, it means saving tons of fuel.

However, the transition to higher parameters requires the use of expensive heat-resistant materials, which leads to an increase in the cost of power plants. If we use a monoblock with a perspective power of 300 MW, then the main dimensions of the elements in the flow section of the turbine's high-pressure cylinder and steam distribution system will change little and will not require new technological processes and modernization. Therefore, it is possible to raise the steam temperature up to 630 0C by using well-known brands of austenitic steels in the pipes inside the boiler and in the high-temperature parts of the main steam line and turbine. In this case, the coefficient of efficiencyis taken to be about 47% [2].

When power units operate with increased parameters, austenitic steels containing 99% chromium-containing P91 and 11% chromium are used. So far, x20 steel is used in the engineering industry. The sliding limit of these metals is shown in Figure 1. As it is seen, the sliding limit of P92 steel is twice that of x20 ⦋3⦌.

The scheme of experimental device of the steam generator is given in Figure 2. The liquid (working body) rotation and pressure in the system are created by a four plunger pump (2). The pump has been provided pressure (1) and soothing container (5). The pressure of the liquid in the system is regulated by needle valves (4, 6, 7, 20, 21 and 24). During the experiment, a preliminary electric heating system (8) has been designed to warm the working body to the required temperature (25–250 0C). Initial electric heating system before and after is designed for the current divider (9). The studied liquid enters the suction tube of pump from the pressure container of working body and heats up to the required temperature, the initial electric heating system passes through three soothing containers (5) under pressure created by the pump and enters the experimental tube (14). The primary electric heating system and the experimental tube are heated by a low- voltage alternating current. For this, the scheme provides two autotransformers (10) and two step-down transformers (11). There is a mixer (13) at the entrance and exit of the experimental tube to measure the average temperature of the liquid. The experimental tube consists of stainless steel 1X18H10T mark with different diameters (d = 1–18 mm), different shapes and different lengths (L = 10–2000 mm). The temperature of the liquid at the entrance and exit of the experimental tube and temperature of the outer surface wall are measured by thermocouples made of chromel–alumel wires with a diameter 0.2 mm. The thermocouple indicators are measured using a digital voltmeter type B7-16A, automatically registering KSP-4 potentiometer, potentiometer PP-63 with ± 0.05 precision limit and digital thermometers.

The pressure of the liquid is measured by the standard manometer (12) (P = 1–400 bar) placed at the inlet and outlet of the experimental tube. Vibration of pressure is determined by the oscillograph mounted on the experimental tube (19).

Figure 2. The schematic description of experimental device of the steam generator with a high pressure

Figure 3 shows the metals used in the blocks with supercritical and ultra-supercritical parameters and the corresponding efficiency coefficients.

The second way to increase the efficiency of thermal power plants is to use intermediate heating. Stations operating with supercritical and ultra-supercritical parameters use double intermediate heating. The aim is to reduce electricity generating expenses and prevent erosion

in the final stages of the turbine's low-pressure cylinder.

Passing to ultra-supercritical starting steam parameters is currently relevant. For this, the industry has a number of strategic goals:

1. Creating a new generation of high-performance power plants.

2. Improving environmentally friendly technologies in facilities.

3. Decommissioning of old equipment, their replacement with new promising equipment.

4. Reduction of specific fuel consumption.

5. Reduction of repair costs.

6. Reduction of harmful substances released into the environment.

As it is mentioned, with the increase of the initial steam parameters, the fuel consumption at the station decreases, efficiency coefficient increases and the amount of emitted harmful wastes (NOxCOx and greenhouse effect creating CO2 gasses) decreases [2]. Figure 4 shows the dependence of CO2 gas on the station's net efficiency. As it can be seen from the graph, as the efficiency increases, the amount of CO2 emitted into the atmosphere decreases ⦋2⦌.

Figure 4. Dependence of CO2 emitted into the atmosphere on the net efficiency (1 - when coal burns, 2 - 3 - when coal burns with biomass, 4 - when natural gas burns)

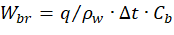

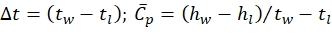

(1)

Where

– is the speed brought.

– is the speed brought.

w-tl - is the average heat capacity.

w-tl - is the average heat capacity.

(1) can be expressed as a dimensionless quantity that characterizes the structure of a flood.

(2)

In engineering reports, the onset of a deteriorating regime can be determined by the enthalpy of the flow and the value of q/⍴u.

Therefore, experiments with water have been carried out in a straight vertical pipe on the experimental rig at different mass velocities at pressures above the critical. The experimental device is mainly used to screen the drum, straight forward and utility boilers of thermal power plants, to eliminate faults in ceiling heating pipes, water economizer, air heaters, to increase, economic efficiency of steam boilers when operating with sliding initial parameters, to reduce the amount of conventional fuel on 1kW/h. It is designed to conduct research to reduce the amount of waste. The test tube is made of stainless steel of different diameters (d_int = 1 ÷ 18mm), shapes, lengths (l_com = 10 ÷ 2000 mm). The test tube is heated by a low-voltage alternating current. Modern devices are used to make measurements. Extensive information is provided about the experimental facility, the procedure and analysis of the experiments [7].

The results of experiments on heat transfer have been analyzed and the dependence K_1 = f(K_2) has been established.

Where K_2 is a dimensionless quantity that characterizes the intensity of heat transfer.

(3)

1. When h_w>h_l then ∆h_w=(h_w-h_l )

2. When h_l>h_w then ∆h_w=(h_l-h_w )

From the dependence K_1 = f(K_2) shown in Figure 6, it can be seen that the vertical line indicates the normal mode of heating, and the horizontal line indicates the mode of deterioration. The point of intersection of the lines K_2^bound indicates the beginning of the degraded mode of heating. An empirical equation has been obtained to determine K_2^bound.

When h_l<0,8h_w

(4)

When h_l>0,8h_w

(5)

Figure 6. Dependence of K1 = f (K2) on the movement of water in a vertical pipe 1-P/Pcr=1,02, ⍴u=430 kg/(m2c); 2-P/Pcr=1,1, ⍴u=449 kg/(m2c); 3-P/Pcr=1,1, ⍴u=595 kg/(m2c); 4 - P/Pcr=1,2, ⍴u=493 kg/(m2c).

(6)

When h_l>h_w

Increasing the initial parameters of steam in thermal power plants with supercritical, ultra-supercritical parameters, using double intermediate heating, raising the number of regenerative heaters, increases the efficiency to 50% and saves fuel. Due to the use of precious metals at these stations, capital costs increase by up to 30%, but this is paid for in 3-4 years. Since the boiler operates at high temperatures, the temperature regime of the heating surface has been studied and the enthalpy has been determined at the boundary where the deterioration mode of the heating coefficient began.

1 R.F. Kalbaliev, D.P. Mamedova, Energy Problems 3-4 (2009) 60.

2 S. Kyaer, Power plants 3 (2002) 63.

3 http://spectali.ru/catalog/zharoprochnyeslave.

4 http://minenergo.gov.ru/node/3378.

5 N.D. Rogalev, Materials of the 7th International Conference of Young Scientists "Electrical Engineering. Electrotechnology, Energy, Novosibirsk Publishing House NGTU (2015) 383.

6 A.S. Sedlov, New in Russian power 9 (2016) 6.

7 J.P. Mammadova, A.P. Abdullayev, R.M. Rzayev, S.H. Mammadova and R.A. Sultanov, Modern Physics Letters B. 34(27) (2020) 2050299.

C.P. Mammadova, A.P. Abdullayev, I.V. Musazade, Improving the efficiency of thermal power plants research methods, UNEC J. Eng. Appl. Sci. 3(1) (2023) 21-27 https://doi.org/10.61640/ujeas.2023.0504

Anyone you share the following link with will be able to read this content:

This article is licensed under the Creative Commons Attribution ( CC BY 4.0 ) License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

R.F. Kalbaliev, D.P. Mamedova, Energy Problems 3-4 (2009) 60.

S. Kyaer, Power plants 3 (2002) 63.

http://spectali.ru/catalog/zharoprochnyeslave.

http://minenergo.gov.ru/node/3378.

N.D. Rogalev, Materials of the 7th International Conference of Young Scientists "Electrical Engineering. Electrotechnology, Energy, Novosibirsk Publishing House NGTU (2015) 383.

A.S. Sedlov, New in Russian power 9 (2016) 6.

J.P. Mammadova, A.P. Abdullayev, R.M. Rzayev, S.H. Mammadova and R.A. Sultanov, Modern Physics Letters B. 34(27) (2020) 2050299.