UNEC Journal of Engineering and Applied Sciences Volume 2 No 1, pages 75-84 (2022) Cite this article, 1414

Currently, a promising niche crop grown in Russia is flax seeds. As a source of essential macronutrients and biologically active substances, they are considered as additional raw materials enriching bakery and flour confectionery products. In terms of protein content (18-25%), they are superior to cereals (9-12%), the amount of essential amino acids in their protein complex is more than 50% higher than that of cereals. Flax seeds are rich in essential polyunsaturated fatty acids with a predominant (more than 50%) content of the family ɷ-3; by the number of lignans (52679 μg / 100 g) belonging to the class of phytoestrogens, which support the most important physiological functions of the human body, they are hundreds of times higher than other crops, including cereals (369 μg / 100 g). Flax seeds are characterized by the presence of soluble dietary fiber localized in their mucus cells, macro- and microelements (Na, Mg, P, Zn) vitamins (A, C, E, B6 [1].

Flax seeds are used in general, crushed, roasted form, as well as in the form of oil and flour in the composition of various food products [2-4]. As a functional product, they provide the body with essential nutrients and, as a nutraceutical, benefit health, providing a preventive effect against various types of cancer, reducing cardiovascular diseases, lowering blood cholesterol levels, etc. [5-9].

The main functional ingredients in the composition of flax seeds include proteins, polyunsaturated fatty acids of class ɷ-3, dietary fibers represented by water-soluble polysaccharides located in the mucous cells of seeds. They are part of the main substances that determine the nutritional value of flax seeds and products of their processing, as well as their functional and technological properties that affect the structural and rheological characteristics of food systems.

The purpose of this study was to study the effect of flax seed ingredients on the biological value and technological characteristics of food systems.

The objects of research were oilseeds, flaxseed flour, as well as flour products prepared with their use.

Samples of bakery products were prepared by the unpaired method according to the method of trial laboratory baking [10].

Raw materials for the manufacture of samples of bakery products were purchased in the retail network complied with generally accepted standards.

The study used generally accepted standardized organoleptic and physicochemical methods of analysis.

To study the microstructure of crumb samples, a scanning microscope from JEOL JSM-5300LV SCANNING MICROSCOPE was used.

The effective viscosity of wheat dough with crushed flax seeds and flaxseed flour was determined on the rotational viscometer "Reotest - RV2", which is designed to determine the dynamic viscosity of Newtonian and non-Newtonian liquids. The content of flaxseed raw materials was 3, 6, 9%. The control was the dough from wheat flour I quality grade. Consistency coefficients were determined, which are a characteristic of the effective viscosity. Effective viscosity shows the flow of pseudoplastic objects when, with an increase in shear stress in the flow process, the original structure is destroyed. Effective viscosity is an integral characteristic that describes the equilibrium state between the processes of restoration and destruction of the structure.

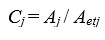

Indicators of the biological value of the protein were calculated in accordance with the sources [11,12]:

Amino acid score (Cj) characterizes the ratio of the amount of essential amino acid in the product (Aj, g / 100 g protein) to its content in the reference protein (Aetj)

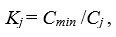

Utility coefficient of the j-th essential amino acid (Kj), fractions of units:

where Cmin is the minimum value of the essential amino acids of the estimated protein in relation to the physiologically necessary norm (standard).

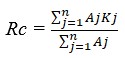

The coefficient of balance of amino acid composition - Rc - numerically characterizes the balance of essential amino acids in relation to the physiologically necessary norm (ethanol), fractions of units:

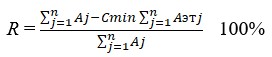

Coefficient of imbalance of amino acid composition R - numerically characterizes the imbalance of essential amino acids of the estimated protein in relation to the physiologically necessary norm (standard). This indicator characterizes the excessive amount of essential amino acids not used for plastic needs

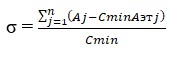

The indicator of comparable redundancy -  - the content of essential amino acids, characterizes the total mass of essential amino acids not used for anabolic needs in the amount of protein of the evaluated product, relative to their potentially recyclable content of 100 g of the reference protein, mg / g of the reference protein:

- the content of essential amino acids, characterizes the total mass of essential amino acids not used for anabolic needs in the amount of protein of the evaluated product, relative to their potentially recyclable content of 100 g of the reference protein, mg / g of the reference protein:

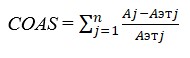

The coefficient of deviation of the values of amino acid composition from reference (COAS) characterizes the total relative value of deviations of the values of essential amino acids from the corresponding reference ones:

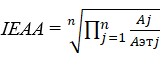

The index of essential amino acids IEAA takes into account the number of all essential amino acids and is determined by the formula:

Analysis of the data of the chemical composition of flax seeds and flaxseed flour (semi-fat-free and fat-free) showed that the main nutrients in them are contained in the following proportions:

To visualize the change in the ratio of the main ingredients during the sequential processing of flax seeds into flour, Figure 1 presents models of matrices of the nutritional value of flax seeds and flaxseed flour, semi-degreased and fat-free.

(a)

Model of the matrix of nutritional value of flax seeds

(b)

Model of the matrix of nutritional value of semi-skimmed flaxseed flour

(c)

Nutritional Value Matrix Model low-fat flaxseed flour

Figure 1. Models of matrices of nutritional value of flax seeds (a) and flaxseed flour: semi-fatten (b) and fat-free (c)

Flax seeds are characterized by a significant content of lipids and protein, flaxseed flour, first of all - a high protein content. It is the reactive groups of these components, some of which are presented in Table 1, first of all, can show different activity when introducing such raw materials into various food systems. At the same time, the activity determines This is due to the nature of functional groups, the conditions of influence on food systems, the parameters of technological processes (temperature, ionic force, etc.) and storage.

Table 1. Some reactive groups of food ingredients [13]

Physicochemical interactions between the components of food systems determine their organoleptic, technological properties, the formation of dispersed systems, such as dough, emulsions, etc.

Proteins in food systems, due to different origins, differ in amino acid composition, amino acid sequence, shape, and, therefore, must have different functional properties. As a result of the interaction of reaction groups of proteins, covalent and non-covalent intermolecular bonds can be formed with subsequent aggregation of proteins, which leads to a change in the functional and technological properties of food systems.

In food systems such as oil-in-water emulsions, the structuring role is played by fat globules distributed in an aqueous dispersion medium. Their interaction with proteins leads to the stabilization of the system.

Polysaccharides, their interactions with each other, proteins and lipids also affect the functional and technological properties of food systems: moisture-retaining capacity, viscosity and other rheological properties [14,15].

Flaxseed flour, as a product of flax seed processing, in addition to a high amount of protein, contains all essential amino acids (EAA). In order to study the effect of flaxseed protein on the complementary composition of NAC composite wheat-flaxseed flour, the balance of its amino acid composition was assessed based on a comparison of the calculated data with the reference values of essential amino acids.

Table 2 presents data on the amino acid composition of wheat and flaxseed flour, used to calculate the indicators of their biological value, as well as composite flour based on them: 90% wheat + 10% flaxseed.

Table 2. NAC content and amino acids of wheat and flaxseed protein

As follows from the data of Table 2, when flaxseed flour is added the minimum amino acid score (for lysine) increases from 52% (for wheat flour) to 73%, that means the increase by 40%.

Also the introduction of flaxseed flour into the composition of composite in the amount of 10% increases the amount of essential amino acids ( ЕАА) which is 40% of the daily requirement for essential amino acids of an adult (weighing 70 kg). Calculated data are presented in Table 3.

Table 3. Assessment of the degree of satisfaction of the daily requirement for amino acids of composite wheat-flaxseed flour.

The amount of essential amino acidsin flaxseed flour containing 25% protein. as shown by calculations (Table 3), is 32.4% higher than the daily requirement for the total amount of essential amino acids.

The obtained values of formalized indicators of the biological value of composite flour containing 10% flaxseed, presented in Table 4. indicate an increase in the biological value of wheat protein when it is supplemented with linseed flour, expressed in an increase in the amount of irreplaceable amino acids by 34.7%, the coefficient of balance of amino acid composition - by 5%, the index of essential amino acids by 37.4%.

Table 4. Biological value of proteins of composite flour and ingredients.

Thus, it is advisable to use flaxseed flour for enrichment with essential amino acids of traditional baking raw materials. in particular wheat flour, the degree of satisfaction of the daily need for NAC of which is 30.7%.

Baking dough refers to a multicomponent colloidal dispersion system. The dough can be represented as a viscoelastic hydrated matrix of gluten proteins with starch grains embedded in it, fragments of cell walls of various sizes, neutral and polar lipids, air and fermentation gases.

The structure of the test is primarily determined by the presence of disulfide bonds. Disulfide bonds are the only covalent cross-links between the side chains of proteins. They are intra- and intermolecular. They are formed when two Cys-residues converge at the appropriate orientation and oxidation of sulfhydryl groups with molecular oxygen occurs. Due to the formation of a connection between the side chains disulfide bonds contribute to the stabilization of the folded structure of the protein.

The addition of flaxseed flour (or ground flaxseeds) to wheat flour during dough production affects the quality of the gluten framework. Flax proteins, having no prolamine fraction, reduce the gluten content in the total protein matrix. At the same time, the carboxyl and hydroxyl groups of polygalacturonic acid molecules, which are the basis of the acidic fraction of linseed mucus polysaccharides, are able to independently react with protein molecules, which leads, in particular, to the formation of additional sulfide bonds in the form of S-S bridges due to the oxidation of S-H groups. flour proteins, "strengthening" the structure of gluten.

Flaxseed mucus polysaccharides are a source of additional sugars, such as arabinose, xylose, galactose, which belong to the class of reducing sugars, and actively interact with proteins and amino acids (Maillard reaction).

Oxidation products of unsaturated fatty acids (linolenic, linoleic) hydroperoxides can act as oxidants and contribute to the formation of transverse disulfide bonds that increase the stability of the structure of flour products.

The interaction of polysaccharides with proteins. lipids affect various functional properties of food systems: moisture-retaining capacity, viscosity and other rheological properties. The presence of polysaccharides such as hydrocolloids (mucus) in the composition of flax seeds will help to increase the moisture content of the dough and finished products.

Our research on the introduction of flaxseed products with different protein content into the baking dough made it possible to identify the features of the test with these components. The characteristics of the laboratory samples of flaxseed products used are presented in Table 5.

Table 5. Characteristics of samples of flaxseed products

Due to the absence of the prolamine fraction in the protein complex of flax seeds, when replacing part of the wheat flour, a decrease in gluten proteins occurs. It was found that, depending on the input amount of the component and the content of functional ingredients in it, the decrease in the content of crude gluten varied between 20-57%; an increase in gluten elasticity - in the range of 19-23 %. The study of the rheological properties of the dough showed that the effective viscosity when adding two types of semi-fat-free and low-fat flour in the amount of 6 and 9%. increased by 22.3 and 264% as well as by 30.7 and 193% respectively (Figure 2). Such an effect on the rheological properties can be exerted by both the additional introduction of protein in the composition of flaxseed flour and polysaccharides of flaxseed mucus. having high hydrophilicity. They are able to easily peptize in water to form viscous gels.

Figure 3. Increase in the specific volume of samples of bakery products when adding flaxseed products

The ratio of the main substances in semi-fat flaxseed flour (proteins: fats: carbohydrates = 3.2: 1: 5.8) was the most optimal for an effective increase in the specific volume of samples of bakery products.

A comparative study of the microstructure of the crumb of bread with the addition of crushed flax seeds and flaxseed flour (semi-fat-free and fat-free) made it possible to maintain differences in the porous structure: the number. size and thickness of pores differed significantly. Samples of bread crumbs with flaxseed additives had a fine-porous structure.

Differences in the microstructure of the crumb of bread with the addition of flax seeds and flaxseed flour are demonstrated by photographs taken at a magnification of 2000 times (Figure 4).

The influence of the component composition. namely the content of lipids. proteins and polysaccharides. is manifested in the microstructure of crumb samples with additives of crushed flax seeds and flaxseed flour. For a bread crumb sample with crushed flax seeds. the predominant oil particles form a fairly uniform bubble coating of starch and protein grains. which can have a significant impact on the rheological properties of the dough in particular by increasing their elasticity (Figure 4 (2)).

1) Control

2) With crushed flax seeds

3) With semi-refined flaxseed flour

4) With skimmed flaxseed flour

Figure 4. Microstructure of wheat bread crumb with additives of crushed flax seeds and flaxseed flour (semi-fat-free and fat-free) with an increase of 2000 times

Due to the high water solubility of mucus polysaccharides, their ability to form gels and complexes with proteins of starch grains are covered with a layer of protein-carbohydrate mass, It is likely that mucus carbohydrates in competition for water molecules prevent a more complete swelling of starch grains, which is manifested in an increase in the viscosity of the dough.

With an increase in the protein content in the case of low-fat flaxseed flour (Figure 4 (4)), the microstructure of the bread crumb is close to the control sample: starch grains are covered with denatured protein globules and a homogeneous protein-carbohydrate film.

The ingredients of flaxseed components are actively involved in the formation of wheat dough due to the resulting protein-lipid, protein-polysaccharide complexes, as well as due to the formation of complexes between flaxseed and wheat proteins.

On the example of studying the influence of functional ingredients on baking dough and finished products, it is shown that flax seeds and products of their processing. along with enrichment, can be a potential regulator of the consistency of food systems.

The influence of functional ingredients of flax seeds on the quality of baking dough was revealed, consisting in reducing the gluten content by up to 57%. depending on the protein component of the flax component; in increasing the elastic properties of the dough by 19-23% as a result of the effect of oxidation products of polyunsaturated fatty acids of the linen component (peroxides) on an increase in the disulfide bonds of the protein matrix, in the synergistic effect of flaxseed proteins and polysaccharides on increasing the effective viscosity of the dough to 264%.

The study of the microstructure of the crumb of bread showed that the components of flaxseed flour are involved in the formulation of the structure of wheat dough, probably due to the formation of protein-lipid, protein-polysaccharide complexes, as well as due to the formation of complexes between flaxseed and wheat proteins.

1 M. Parikh, T.G. Maddaford, J.A. Austria, M. Aliani, T. Netticadan, G.N. Pierce, Nutrients 11(5) (2019) 1171.

2 M. Aliani, D. Ryland, G.N. Pierce. J Food Sci. 77(1) (2012) 62.

3 P. Marpalle, S.K. Sonawane, S.S. Arya, LWT. Food Sci Technol. 58 (2014) 614.

4 T.B. Tsyganova, I.E. Minevich, L.L. Osipova, Storage and processing of agricultural raw materials. 2 (2019) 24.

5 T. Amin, M. Thakur, Online International Interdisciplinary Research Journal. {Bi-Monthly}. IV(I) (2014) 220.

6 A.K. Sahoo, C. Rahul, International Journal of Pharmaceutical Sciences Re- view and Research 31(1) (2015) 42.

7 A. E-D. Bekhit, A. Shavandi, T. Jodjaja, J. Birch, S.Teh, J.A.M. Ahmed, F. Al-Juhaimi, P. Saeedi, A. A. Bekhit, Biocatalysis and Agricultural Biotechnology 13(1) (2018) 129.

8 A. Goyal, V. Sharma, N. Upadhyay, S. Gill, M. Sihag, J Food Sci Technol. 51(9) (2014) 1633.

9 T.B. Tsyganova, I.E. Minevich, V.A. Zubtsov, L.L. Osipova, Nutritional value of flax seeds and promising areas of their processing. Kaluga. Eidos Publishing House (2010) 128p.

10 T.B. Tsyganova, Technology and organization of production of bakery products. M.. Publishing Center "Academy" (2006) 448p.

11 N.N. Lipatov, G.Yu. Sazhinov, O.N. Bashkirov, Storage and processing of agricultural raw materials 8 (2001) 11.

12 A.B. Lisitsyn, M.A. Nikitina, E.B. Sus, Food Industry 1 (2016) 26.

13 S. Damodaran, K.L. Parkin, O.R. Fennema (ed.-comp.), Chemistry of food products, Publishing House "Profession" (2017) 1040 p

14 H.H. Ding, S.W. Cui, H.D. Goff, Q. Wang, J. Chen, N.F. Han, Food Research International 56 (2014) 166.

15 P.V. Sannikov, Food Systems 4(3S) (2021) 237

T.B. Tsyganova, I.E. Minevich, Flax seeds as regulators of biological value and technological characteristics of food systems, UNEC J. Eng. Appl. Sci 2(1) (2022) 75-84

Anyone you share the following link with will be able to read this content:

This article is licensed under the Creative Commons Attribution ( CC BY 4.0 ) License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

M. Parikh, T.G. Maddaford, J.A. Austria, M. Aliani, T. Netticadan, G.N. Pierce, Nutrients 11(5) (2019) 1171.

M. Aliani, D. Ryland, G.N. Pierce. J Food Sci. 77(1) (2012) 62.

P. Marpalle, S.K. Sonawane, S.S. Arya, LWT. Food Sci Technol. 58 (2014) 614.

T.B. Tsyganova, I.E. Minevich, L.L. Osipova, Storage and processing of agricultural raw materials. 2 (2019) 24.

T. Amin, M. Thakur, Online International Interdisciplinary Research Journal. {Bi-Monthly}. IV(I) (2014) 220.

A.K. Sahoo, C. Rahul, International Journal of Pharmaceutical Sciences Re- view and Research 31(1) (2015) 42.

A. E-D. Bekhit, A. Shavandi, T. Jodjaja, J. Birch, S.Teh, J.A.M. Ahmed, F. Al-Juhaimi, P. Saeedi, A. A. Bekhit, Biocatalysis and Agricultural Biotechnology 13(1) (2018) 129.

A. Goyal, V. Sharma, N. Upadhyay, S. Gill, M. Sihag, J Food Sci Technol. 51(9) (2014) 1633.

T.B. Tsyganova, I.E. Minevich, V.A. Zubtsov, L.L. Osipova, Nutritional value of flax seeds and promising areas of their processing. Kaluga. Eidos Publishing House (2010) 128p.

T.B. Tsyganova, Technology and organization of production of bakery products. M.. Publishing Center "Academy" (2006) 448p.

N.N. Lipatov, G.Yu. Sazhinov, O.N. Bashkirov, Storage and processing of agricultural raw materials 8 (2001) 11.

A.B. Lisitsyn, M.A. Nikitina, E.B. Sus, Food Industry 1 (2016) 26.

S. Damodaran, K.L. Parkin, O.R. Fennema (ed.-comp.), Chemistry of food products, Publishing House "Profession" (2017) 1040 p

H.H. Ding, S.W. Cui, H.D. Goff, Q. Wang, J. Chen, N.F. Han, Food Research International 56 (2014) 166.

P.V. Sannikov, Food Systems 4(3S) (2021) 237